- Business Process Management (BPM)Document Management System (DMS)Electronic Quality Management System (QMS)Risk, Governance & Compliance (GRC)Low Code Rapid Application Development (LC)Business Continuity Management (BCM)Enterprise Architecture (EA)Business Process Management (BPM)Document Management System (DMS)

- Document Control Overview

- AI Content Creation & Improvement

- Policy & Procedure Management (SOP)

- AI Content Mining Parser

- Collaboration & Governance

- Data Migration & Integration

- Interfacing Offline App

Electronic Quality Management System (QMS)

Electronic Quality Management System (QMS)- Quality Management System Overview

- Document Control & Records Management

- Audit & Accreditation Management

- Corrective & Preventative Action

- Quality Event (Non-conformity / Complaint/ Compliance)

- Risk Management

- Incident Management

- Environmental Health & Safety

- Product & Supplier Management (SCAR)

- Training Management

- Control Management

- Action Items Management

- Management Review

- FMEA

- Pharmacovigilance

- Data Migration & Integration

Risk, Governance & Compliance (GRC)

Risk, Governance & Compliance (GRC)- Risk, Governance & Compliance Overview

- Risk & Control Management

- Regulatory Compliance

- Collaboration & Governance

- Data Migration & Integration

- Interfacing Offline App

Low Code Rapid Application Development (LC)

Low Code Rapid Application Development (LC)- Low Code Automation Platform Overview

- Electronic Web Form Design (eFORMS)

- Database Table Entity Designer

- System Integration Designer

- Design & Manage Tasks

- Design & Manage BPMS Apps

- Custom Rules/Guards/Actions

- Electronic Services

- User Homepage

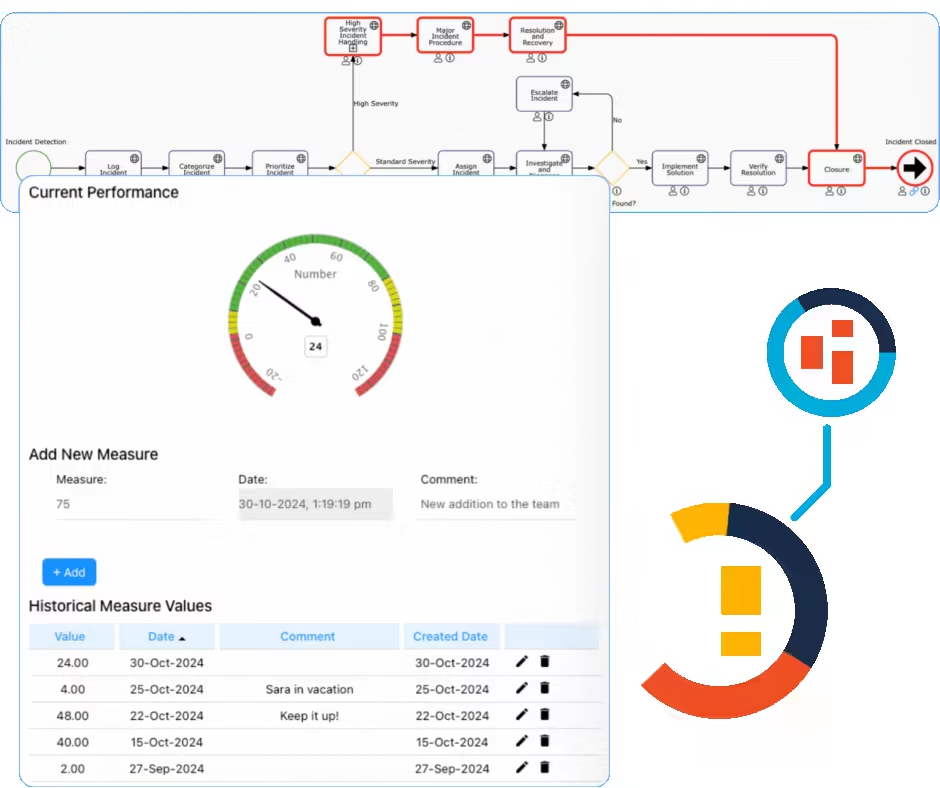

- BAM (Business Activity Monitoring)

- Custom Dashboard Design

- Data Migration & Integration

Business Continuity Management (BCM)

Business Continuity Management (BCM)- Business Continuity Management Overview

- Business Impact Analysis

- Disaster Recovery Simulation

- Action Item Management

- Mass Notification Management

- Asset Management

- Interfacing Offline App

Enterprise Architecture (EA)

Enterprise Architecture (EA) - IndustriesRegulatory ComplianceUse CasesLearning CenterFramework & PracticesIndustries

- Healthcare

- Medical Device Technology

- Life Science, Pharmaceutical

- Aerospace & Defense

- Airlines and Aviation

- Media & Telecommunications

- Government and Military

- Technology

- Energy

- Logistics & Port Operations

- Banking & Capital Markets

- Retail & Consumer

- Consulting

- Education

- Engineering & Construction

- Manufacturing

- Financial Services

- Insurance

- Chemicals

Regulatory Compliance- Regulatory Compliance

- ISO

- ISO 9001 (guide)

- ISO 9001:2026 (preparation)

- ISO 17025

- ISO 27000

- ISO 27001

- ISO27002

- ISO 42001

- EU AI Act

- SOC 2 Type 1 & 2

- Sarbanes Oxley

- GxP

- GRC

- Basel

- Digital Signature

- GDPR

- IFRS

- NIST SP 800-53

Use Cases

Use Cases- Quality Management System (QMS)

- Digital Transformation

- Continuous Improvement

- Governance, Risk & Compliance

- Knowledge Management

- System Deployment (ERP, CRM…)

Learning CenterFramework & Practices

Learning CenterFramework & Practices - AboutCustomer SuccessPartners

Analysis & Improvement

Please Select contact form.

Interfacing empowers your organization with efficient governance through process-based solutions for quality, performance, and compliance management.

Business Process Improvement & BPA Analysis

Business Process Analysis & Continuous Improvement

Business process analysis is the structured review of how work is performed, helping organizations identify inefficiencies, bottlenecks, and opportunities for improvement. When paired with continuous improvement, organizations can systematically enhance processes to boost performance, reduce waste, and align operations with strategic goals.

Interfacing’s Business Process Analysis & Improvement capabilities empower organizations to analyze, improve, and optimize end-to-end business workflows for greater efficiency, quality, and quality and compliance. By connecting process insights with performance metrics and governance outcomes, teams can drive measurable business results and maintain audit-ready process excellence.

Value-based Lean Analysis

Quantitative Reporting

Users can have access to total lead times, which include waiting, processing, transportation time, etc. The EPC can also generate detailed time-study analysis showing key metrics such as cycle time efficiency, total queue time, and total process costs.

Impact Assessment for Planning Business Continuity

By using the Maturity tab in the “Governance” module, users can set up to five different target maturity levels, monitor current status of any process, then plan improvements scheduled by the organization via periodical reviews.

Continuous Improvement Lifecycle Management

Detailed Analytics for EPC Usage

Generate a Process Map in a Few Clicks

Discover the power of our feature as it effortlessly generates detailed end-to-end process map.

What do we mean by “end-to-end”? The A.I. takes care of automatically creating processes that include:

- Flow objects

- Materials

- Annotations

- Assigned responsible roles

- Flow Object Descriptions

This streamlined process ensures a comprehensive representation of your workflow, saving you time and effort.

Elevate Your Operations: Bridging Gaps, Enhancing Efficiency

Immerse your organization in the transformative capabilities of our AI system. It delves deep into your existing processes, unveiling previously unnoticed gaps, inefficiencies, and errors.

With the power of AI, your documentation takes on a dynamic life, consistently evolving and adapting to the ever-changing business landscape. It’s not just documentation; it’s a living entity that grows with your business.

Quick and Tailored Content on Demand

Imagine effortlessly obtaining fresh, tailor-made documentation to meet your specific needs, infused with your unique best practices, operating systems, and country-specific requirements.

Organizations can automate the creation of:

- Step-by-step guides

- Rule and System descriptions

- Policies

- Documentation templates

Step into a new standard in documentation creation, where customization converges with automation.

Elevate Your Documentation: AI’s Seamless Upgrade from Outdated Content

Explore the incredible capability of our AI to smartly enhance your outdated content, creating a strong foundation for fresh and improved documentation.

Our AI ensures you don’t need to reinvest when making the move from the old to the new, saving time and resources without compromising quality.

Precision Automation for Regulatory Compliance

Extend the capabilities of Interfacing’s AI system beyond process creation to ensure precision automation in regulatory compliance, risk management, and control libraries.

Automatically identify regional and industry-specific compliance needs, create comprehensive risk registries for assessment, and generate dynamic control libraries for enhanced governance.

With precision and automation, our AI system paves the way for a robust and resilient business environment.

Empowering Proactive Risk Management

Unlock the power of Interfacing’s AI system as a proactive shield for risks and controls. In a world where manual procedures often lead to non-compliance risks, our AI acts as a shield against such issues.

By proactively advising users of potential compliance conflicts, it ensures your processes adhere to regulatory standards.

The AI not only digitizes activities, eliminating redundancies but also becomes a guiding force in risk management and control libraries.

Discover the

Benefits of Business Process Simulation

Real world scenarios of business process models tested using a low cost and low risk method

Quickly identify disrupting processes to effectively eliminate bottlenecks

Resources that are required are allocated accurately and effectively to complete processes

Assists organizations in making informed decisions with greater accuracy

All ‘what if’ questions are answered when optimizing any process

Documentation and data information provided on different proposals to support ROI

EPC delivers high performance business process simulations. It only takes a few seconds, using thousands of process instances to conduct a simulation. The simulation will provide you with the Key Performance Indicators (KPIs) of any scenario using a business process as well as the activity-based statistics related to each individual process. As an example, visualizing bottlenecks in a particular process can be achieved by creating a heat map.

It’s important to note that you will need a BPMN 2.0 notation business process model and a simulation scenario prior to conducting a simulation. For example:

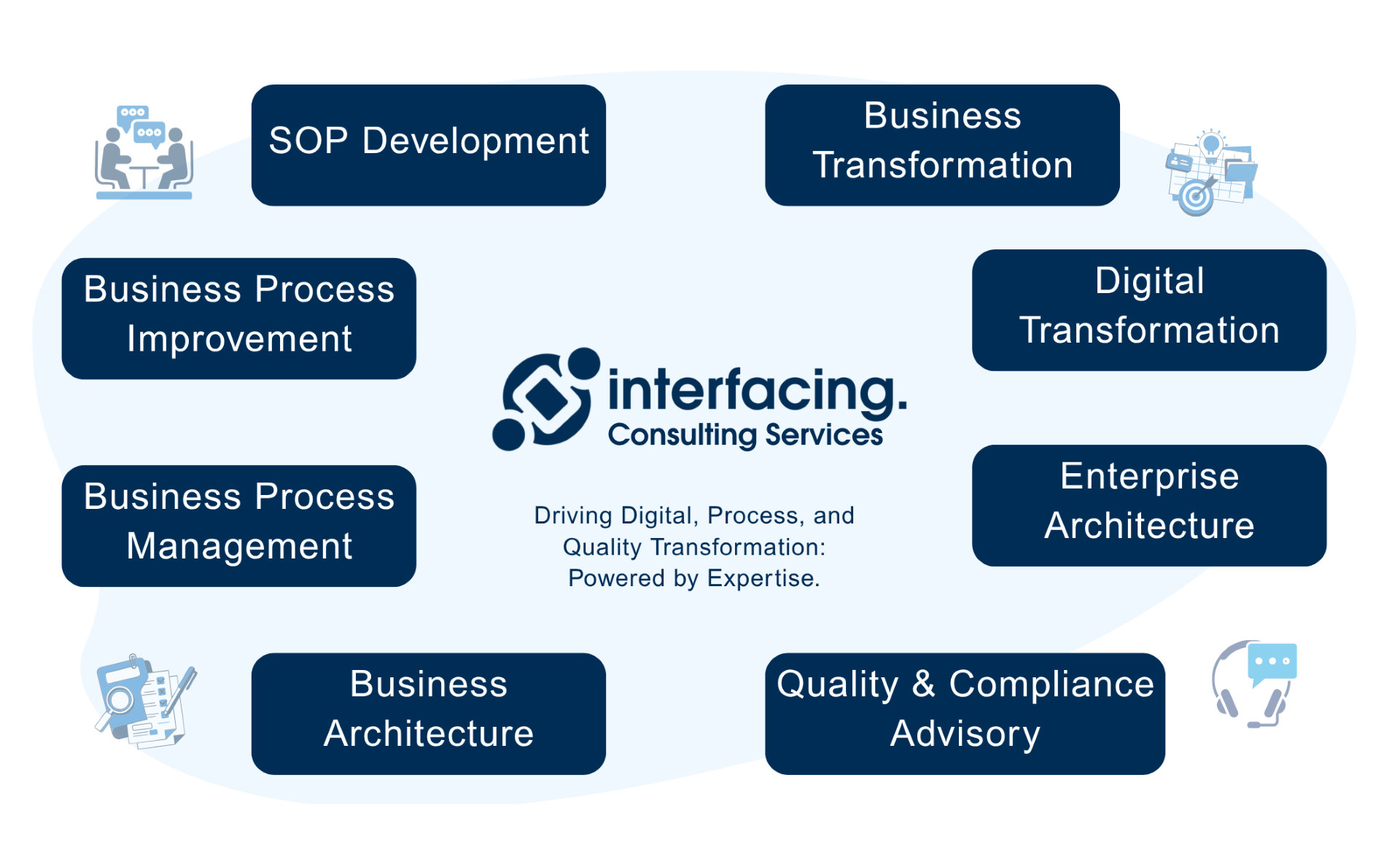

Why Choose Interfacing?

With over two decades of AI, Quality, Process, and Compliance software expertise, Interfacing continues to be a leader in the industry. To-date, it has served over 500+ world-class enterprises and management consulting firms from all industries and sectors. We continue to provide digital, cloud & AI solutions that enable organizations to enhance, control and streamline their processes while easing the burden of regulatory compliance and quality management programs.

To explore further or discuss how Interfacing can assist your organization, please complete the form below.

Documentation: Driving Transformation, Governance and Control

• Gain real-time, comprehensive insights into your operations.

• Improve governance, efficiency, and compliance.

• Ensure seamless alignment with regulatory standards.

eQMS: Automating Quality & Compliance Workflows & Reporting

• Simplify quality management with automated workflows and monitoring.

• Streamline CAPA, supplier audits, training and related workflows.

• Turn documentation into actionable insights for Quality 4.0

Low-Code Rapid Application Development: Accelerating Digital Transformation

• Build custom, scalable applications swiftly

• Reducing development time and cost

• Adapt faster and stay agile in the face of

evolving customer and business needs.

AI to Transform your Business!

The AI-powered tools are designed to streamline operations, enhance compliance, and drive sustainable growth. Check out how AI can:

• Respond to employee inquiries

• Transform videos into processes

• Assess regulatory impact & process improvements

• Generate forms, processes, risks, regulations, KPIs & more

• Parse regulatory standards into requirements

Request Free Demo

Document, analyze, improve, digitize and monitor your business processes, risks, regulatory requirements and performance indicators within Interfacing’s Digital Twin integrated management system the Enterprise Process Center®!

Integration

Discover how we helped other Companies succeed